- Latest CAD/CAM Software linked directly to toolmaking capabilities

- Stratasys 3D Printing for fast prototypes.

- Hexagon 3D Laser Scanning for reverse engineering

- Mould Flow Analysis for simulation of plastic flow in Injection Mould Tools

- Advanced Material Selection capabilities with University qualified Polymer Technologists.

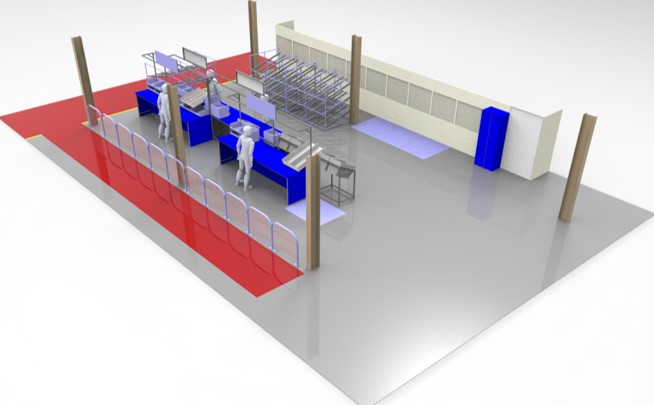

- Over 70 Injection Moulding Cells on two sites with comprehensive ancillary equipment including 3/4/5/6 axis robots. The flexible cells enable short and long production capabilities to suit our customer requirements

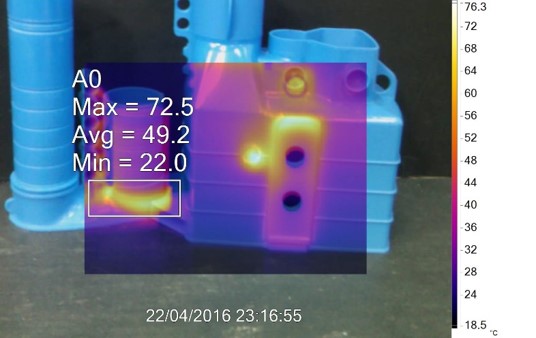

- Thermal Image Analyser for assessment of tooling and component temperatures after moulding

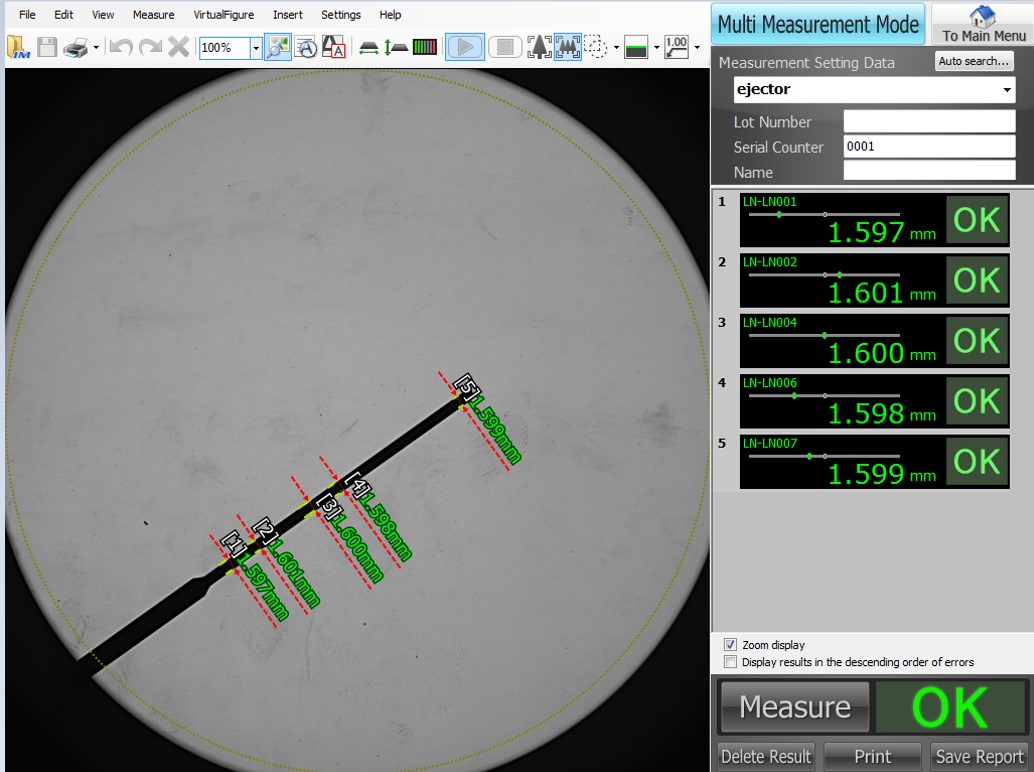

- Automated Image Dimension Measurement System for accurate measurement of components

- Own Branded range of products:- Concrete Spacers, Small Containers, Corner protectors and Tildawn Hazard Warning Lamps

- Project Management of tooling projects for toolrooms in-house, UK and overseas

- Fully Equipped Assembly areas with Welding, Printed and Testing capabilities